Our Products & Services

Internal Fusion Bonded Epoxy (FBE) coating of Flow lines

Internal Fusion Bonded Epoxy (FBE) coating of Flow lines

The facility designed to handle pipes from 4 to 24" diameter and up to 13 meters in length

Automated plant having Full control of powder deposition leading to a consistent coating

Auto indexing system allowing pipes to roll through the ovens ensuring an even consistent pipe temperature

The plant & equipment layout have been designed to facilitate a smooth process flow and incorporate advanced automation technologies to ensure product quality and performance

Automatic abrasive blast system

Full control of powder deposition, resulting in a consistent coating

Custom Internal FBE Coating of Bends, Fittings & Spools

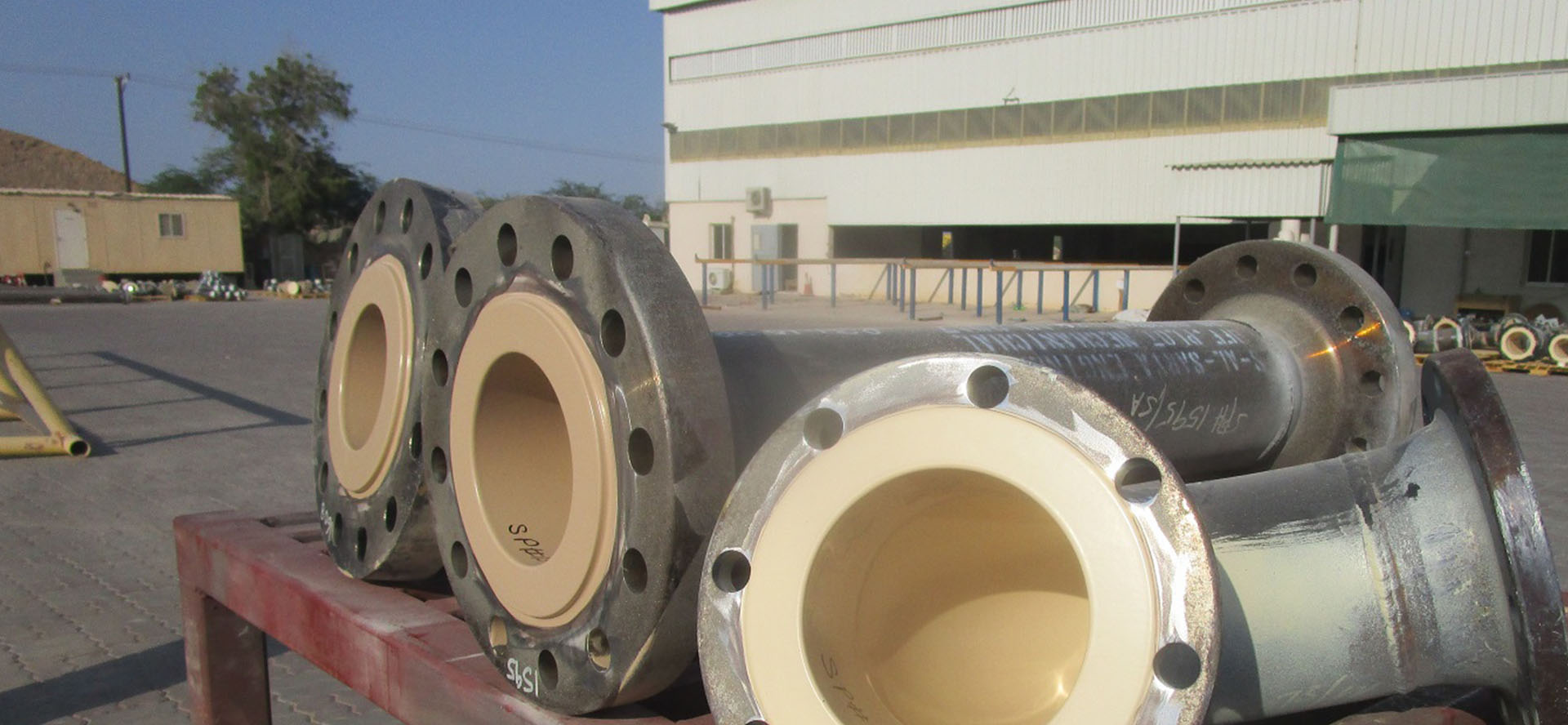

Joining Sleeve for Pipes/Bends/Spools/Fittings– Flo Sleeve™

Joining Sleeve for Pipes/Bends/Spools/Fittings– Flo Sleeve™

Flo-sleeve™ is a welded connection barrier system for joining internally coated line pipe and piping systems

The Flo-sleeve™ connection system utilizes insert sleeve designed as a weld barrier system

Flo-sleeve™ insert fittings provide the same protection and can be fabricated for any configuration, providing an economical and flexible method for field construction, tie-in's, terminations, modifications and repair of internally coated lines

These products are compatible with all IMOS™ FBE coatings and can be used in both onshore and offshore applications.

IMOS facility is capable to manufacture the

flo-sleeve TM from 2" to 32".

flo-sleeve TM from 2" to 32".

Drill Pipe Internal Coating

Drill Pipe Internal Coating

The coating application is required for Corrosion Protection and Hydraulic efficiency

IMOS can coat both new and used pipe

The ability to coat Drill Pipes up to 13 meters in length

Automated plant ensuring quality and consistency

Liquid Epoxy Coating

Liquid Epoxy Coating

Liquid Epoxy application uses a two-pack liquid epoxy paint system, which is applied in a single coat an anticorrosion protection for steel pipes

In the first process, the pipes undergo a cleaning & abrasive blasting operation. liquid epoxy is applied to the inner surface of the pipes by spray forming a uniform single layer epoxy which cures after application.

Drill Pipe Hard Banding

Drill Pipe Hard Banding

Average well depths have increased over the past decade and directional and extended-reach drilling have become more commonplace. These highly deviated paths and associated increases in torque and drag have exerted unprecedented force on the drill pipe

Hard banding has long been acknowledged as an effective means of preventing tool joint wear

This in turn helps to reduce overall cost of replacements significantly